The variety of surface processing of stainless steel broadens its application field. Different surface processing makes it have different surfaces, which makes it unique in application. In the field of architectural application, the surface processing is important for many reasons.

First, the basic types of surface processing

There are roughly five kinds of surface processing that can be used for stainless steel, and they can be combined to transform more final products.

The five types are:

1. Rolling surface processing

2. Mechanical surface processing

3. Chemical surface processing

4. Reticulated surface processing and color surface processing

There are also some special surface treatments, but no matter which surface treatment is specified, the following steps should be followed:

1. Work with the manufacturer to agree on the required surface processing, and it is best to prepare a sample as the standard for mass production in the future.

2. When it is used in a large area, such as composite board, it must be ensured that the base coil or coil used is the same batch.

3. The manufacturing process should be taken into account when selecting the surface processing. For example, in order to remove the weld bead, it is possible to grind the weld and restore the original surface processing. It is difficult or even impossible for diamond plate to meet this requirement.

4, for some surface processing, grinding or polishing lines are directional, called unidirectional. If the grain is vertical instead of horizontal when used, dirt will not adhere to it easily and it will be easy to clean.

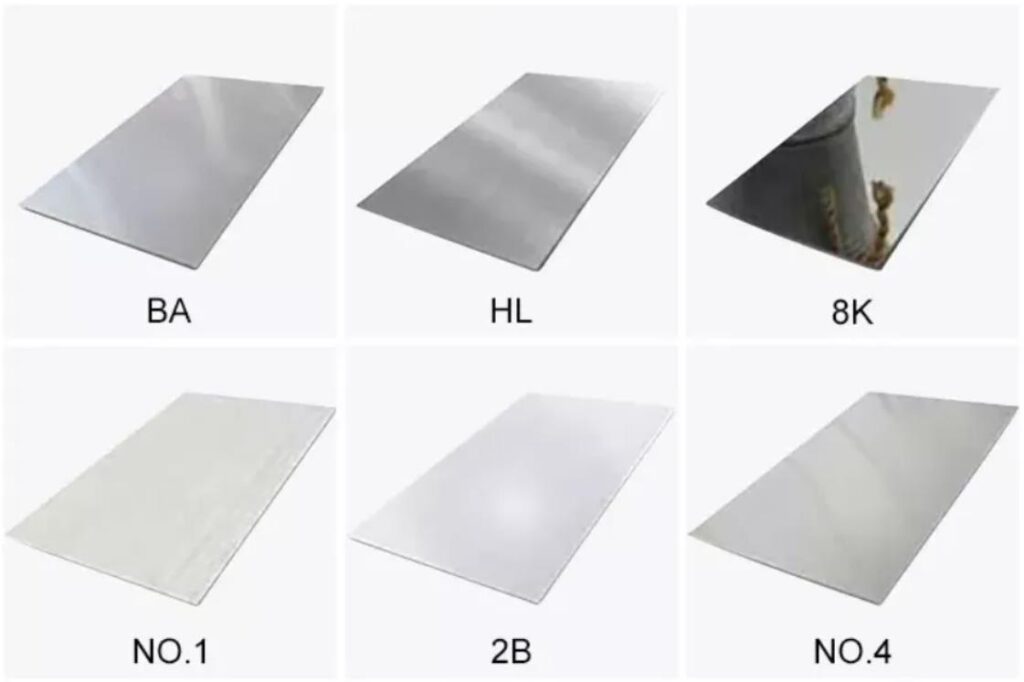

Second, the rolling surface processing

There are three basic kinds of rolling surface processing for plate and strip, which are expressed by the production process of plate and strip.

No.1: hot rolling, annealing, pickling and descaling. The surface of the treated steel plate is a dull surface, which is a little rough.

No.2D: It is better than the surface of N0.1, and it is also a dull surface. After cold rolling, annealing and descaling, it is finally lightly rolled with a rough roller.

No.2B: This is the most commonly used in building applications. Except for the last light cold rolling with polishing roller after annealing and descaling, the other processes are the same as 2D, and the surface is slightly luminous, so it can be polished.

No.2B bright annealing: This is a reflective surface, which is rolled by a polishing roller and finally annealed in a controlled atmosphere. Bright annealing still maintains its reflective surface and does not produce scale. Because there is no oxidation reaction during bright annealing, there is no need for pickling and passivation.

Third, polishing surface processing

No.3: denoted by 3A and 3B. 3A: The surface is evenly ground, and the abrasive particle size is 80 ~ 100. 3B: The rough surface is polished, with uniform straight lines on the surface, which is usually made by once polishing on 2A or 2B board with abrasive belt with particle size of 180 ~ 200.

No.4: One-way surface processing, which is not reflective, may be the most widely used in building applications. The process steps are as follows: firstly, polishing with coarse abrasive, and finally grinding with abrasive with particle size of 180.

No.6: It is a further improvement of No.4, which is to polish the surface of No.4 with tampico polishing brush in abrasive and oil media. This surface finish is not found in British Standard 1449, but it can be found in American Standard.

No.7: it is called bright polishing, which is to polish the surface that has been ground very finely but still has wear marks. Usually, 2A or 2B plates are used, and the wheels and corresponding polishing paste are polished with fiber or cloth.

No.8: mirror polished surface, with high reflectivity, is usually called mirror surface processing because the reflected image is very clear. Stainless steel is continuously polished with a fine abrasive, and then polished with a very fine polishing paste. In architectural application, it should be noted that this kind of surface will leave fingerprints if it is used in places where people flow a lot or people often touch it. Handprints can of course be erased, but sometimes they affect the appearance.

Fourth, the surface roughness

The classification of rolling surface processing and polishing surface processing is to explain the degree that can be achieved, and another effective expression method is to measure surface roughness. The standard measurement method is called CLA (mean value of center line). The measuring instrument moves laterally on the surface of steel plate and records the variation range of peak and valley. The smaller the number of CLA, the smoother the surface. The final results of different grades can be seen from the surface finish and CLA number in the table below.

V. Mechanical polishing

Note: We should remember that grinding with sandpaper or abrasive belt in grinding operation is basically a polishing and cutting operation, leaving fine lines on the surface of steel plate. We had trouble using alumina as abrasive, partly because of pressure. Any grinding parts of the equipment, such as abrasive belt and grinding wheel, must not be used in other non-stainless steel materials before use. Because it will pollute the stainless steel surface.

Six, electrolytic polishing

This is a metal removal process, in which stainless steel is used as the anode in the electrolyte, and the metal is removed from the surface after electrification. This process is usually used to process parts, because their shapes are difficult to be polished by traditional methods. The process is often used for the surface of cold-rolled steel plate because its surface is smoother than that of hot-rolled steel plate. However, electrolytic polishing will make the impurities on the surface more obvious, especially the materials stabilized by titanium and niobium will make the weld zone different due to granular impurities.

Small welding scars and sharp edges can be removed by this process. This process focuses on dealing with the protruding parts on the surface and gives priority to dissolving them. Electrolytic polishing process is to soak stainless steel in heated liquid, and the ratio of liquid involves many proprietary technologies and patented technologies. The electrolytic polishing effect of austenitic stainless steel is very good.

Seven, reticulate surface processing

There are many patterns that can be used in stainless steel. The advantages of adding patterns or reticulate surface processing to the steel plate are as follows:

1) Reduce “oil can-ning”, which is a term used to describe the surface of bright materials, which is uneven from the optical point of view. For example, it is difficult to make the surface of a large-area decorative board completely flat even after stretching and straightening, so the metal roofing material will shrink.

2) Reticulated patterns can reduce glare in the sun.

3) If diamond plate has slight scratches and small area indentation, it is not obvious.

4) Increase the strength of the steel plate.

5) It provides a choice for architects. Patented patterns include cloth pattern (used in Ed House in London), mosaic pattern, pearl pattern and leather pattern. Corrugated and linear patterns can also be used. The patterned surface is especially suitable for interior decoration, such as elevator panels, counters, siding and entrances. When applied externally, it should be considered that stainless steel can be washed by rain and manual scouring, so as to avoid dead corners that are easy to collect dirt and air impurities, so as not to cause corrosion and affect the appearance.

Eight, rough surface processing

Rough surface processing is one of the most commonly used surface processing, which is to polish the polished or bright annealed steel plate surface with nylon abrasive